| Overview |

| Test Setup |

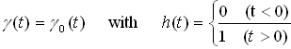

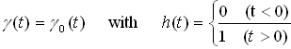

During a step strain or relaxation test, the material is subjected to a step shear strain at the time t = 0.

The response of the material, the stress s(t), is a decreasing function with time. The relaxation modulus is defined as:

G(t) is a monotonic function. G(t → 0) = G0 the glass modulus; G(t → ∞) = Ge the equilibrium modulus, which is zero for thermoplastic melts. For infinitesimal deformation, i.e., if go → 0 , G(t) becomes independent of go , and is referred to as linear viscoelastic shear modulus.

In the rheometer, the strain does not change instantaneously. Instead, the strain is ramped up to the desired value over a very short, nevertheless measurable, period of time. The time required depends on the magnitude of the step, the power of the actuator, the control settings, and the stiffness of the material. The typical response time is in the order of 10 ms for a 10 mrad step.

The material function obtained from a relaxation test is the modulus. If the modulus is obtained from the measured stress and the command strain, the modulus goes through a maximum below 0.1 seconds. Due to the delayed response of the motor, the stress response of the material is not instantaneous as expected. In order to avoid underestimating modulus at short time, the material function is calculated from the measured stress and the actual (measured) strain. It is useful to look at the results in a linear representation also. The modulus in a relaxation experiment drops exponentially after the commanded strain has been reached. From an experimental point of view, this is not the best experiment to perform on predominately viscous materials, because the torque relaxes to fast and the instrument operates most of the time at the low end of the torque range.

To select a Step (Transient) Stress Relaxation test, see Using Experimental Procedures for detailed instructions.

When you perform a Step (Transient) Stress Relaxation test, the following parameters need to be chosen.

Select the following environmental control parameters:

Set up the following test parameters.

Strain rise time: The motor cannot perform an instantaneous deformation step. Enter a rise time (default is 0.01 seconds) to optimize the start up and minimize the strain overshoot. For low-viscosity materials, a longer rise time provides better start up behavior.

Save image: Select to store images of the test within the data file for future recall when using the Camera accessory.

TRIOS Software allows you to define conditions in which a step is halted ahead of its normal termination conditions (Limit checking). You can use this to ensure that, for instance, the instrument does not over speed or apply excessive strains.

Rather than running a step for a certain amount of time, you may wish to run it until stable data is obtained. You can set an Equilibrium limit (such as the viscosity value becoming constant when running a single shear with time) that will stop the currently active test.