| Overview |

| Test Setup |

In a step strain rate test, the deformation rate is stepped from zero to g0 at t = 0.

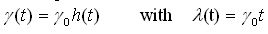

The response of the material to the strain rate step is the stress s(t). The material function is the time-dependent viscosity function:

The linear viscoelastic viscosity function h(t) is independent of g0. In a step rate test (stress growth), a step strain rate is applied and the stress is recorded over time. At a constant strain rate the sample strain increases linearly with time. The stress response increases from zero, and exponentially approaches a steady state value. (stress growth).

When the step rate experiment is performed using a cone and plate geometry, viscoelastic fluids generate a normal stress, which is measured as normal force. The normal stress increases from zero to reach a steady state value, similar to the shear stress.

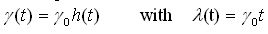

The first normal stress coefficient  can be obtained from first normal stress difference

can be obtained from first normal stress difference

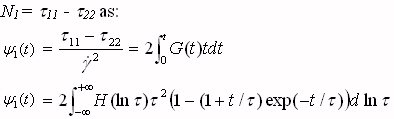

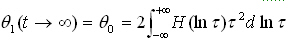

The first normal stress coefficient reduces for t→∞ (steady state flow) to:

reduces for t→∞ (steady state flow) to:

The start up curve of the transient shear stress and predominately the normal stress depends on the response time of the actuator and the instrument compliance. Below 0.1 seconds, the stress growth is significantly affected. Similar to the stress relaxation test, better short time response is obtained when the viscosity function and the normal stress coefficient are evaluated, based on the actual rate and not the command rate.

In the linear region at low rate, the viscosity curves superpose, and the viscosity is independent of the shear rate. With increasing rate, the viscosity becomes non linear and at high rates exhibits a stress over-shoot. The normal stress shows the same behavior. The stress growth experiment is predominately used to measure the non linear viscous (viscosity) and elastic (normal stress) behavior of a viscoelastic material.

To select a Step (Transient) Rate i.e. Stress Growth test, see Using Experimental Procedures for detailed instructions.

When you perform a Step (Transient) Rate test, the following parameters need to be chosen.

Select the following environmental control parameters:

Set up the following test parameters.

Save image: Select if you want to collect images using the furnace camera or any webcam connected.

TRIOS Software allows you to define conditions in which a step is halted ahead of its normal termination conditions (Limit checking). You can use this to ensure that, for instance, the instrument does not over speed or apply excessive strains.

Rather than running a step for a certain amount of time, you may wish to run it until stable data is obtained. You can set an Equilibrium limit (such as the viscosity value becoming constant when running a single shear with time) that will stop the currently active test.